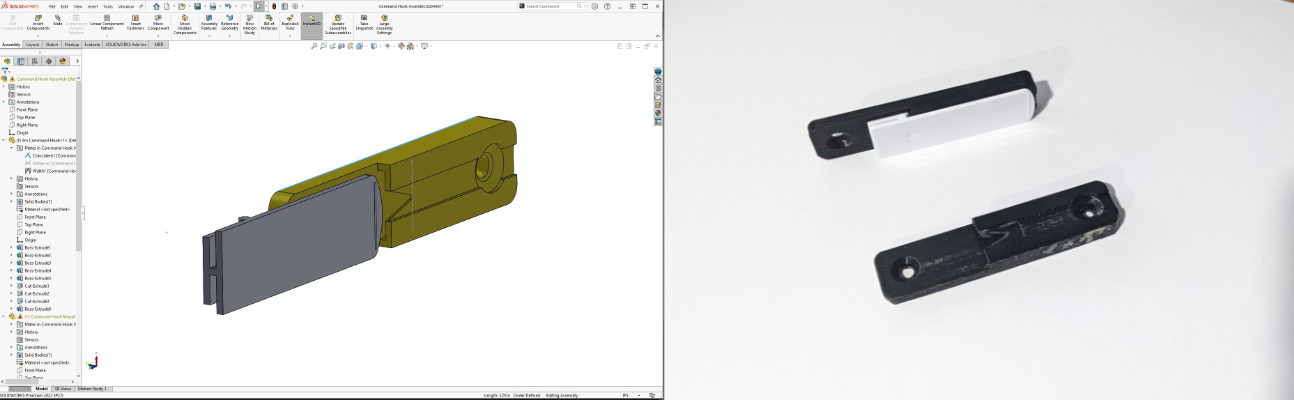

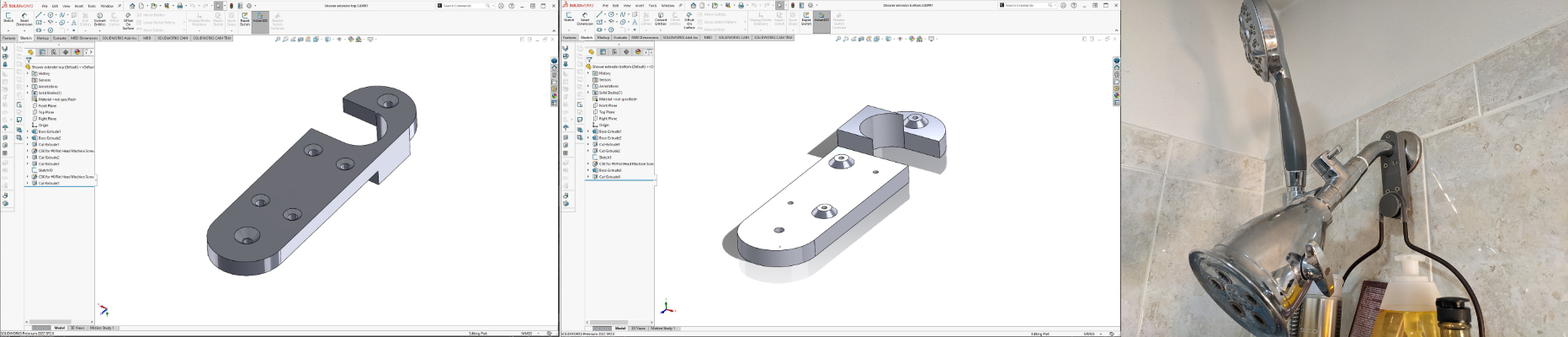

Wanted a custom mountable command hook I could use on projects. I started by modeling the hook itself in Solidworks and then made a female piece that would interlock.

Wanted a custom mountable command hook I could use on projects. I started by modeling the hook itself in Solidworks and then made a female piece that would interlock.

My CNC touch probe was basically just laying around on my CNC table and I was afraid the wire was going to get broken over time. I modeled it in Solidworks and printed it. I needed a few iterations to iron out some ergonomics/placement.

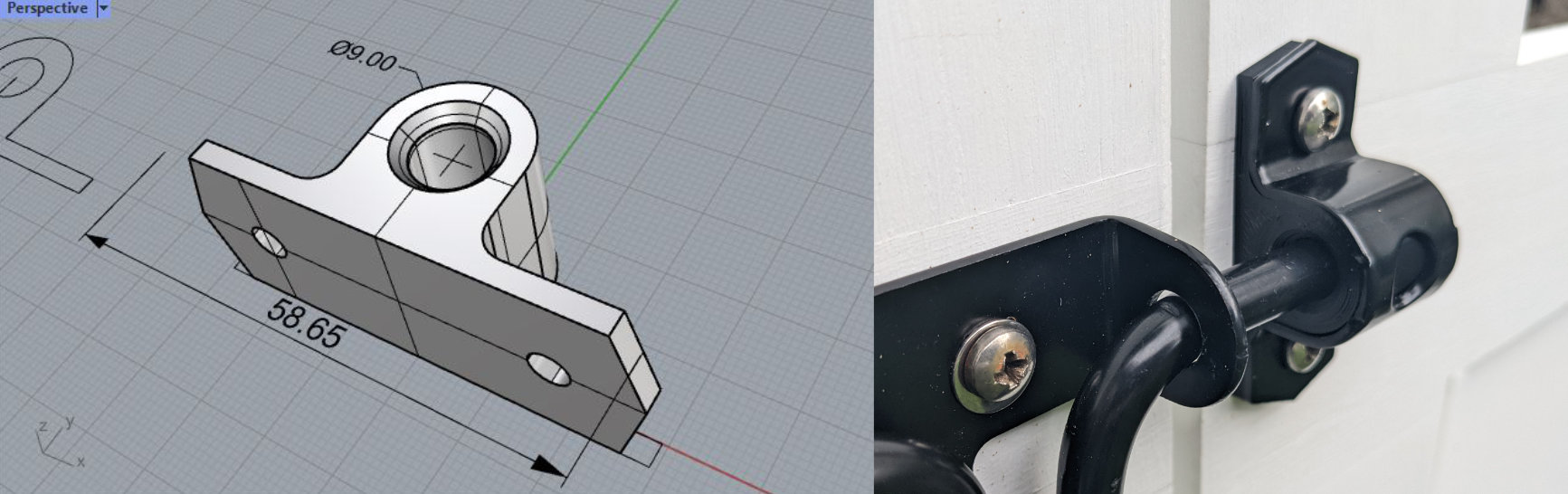

My custom built outdoor gate's latch needed some tweaking for a nice tight fit. Drew up and printed a quick insert that fit the bill. Works great!

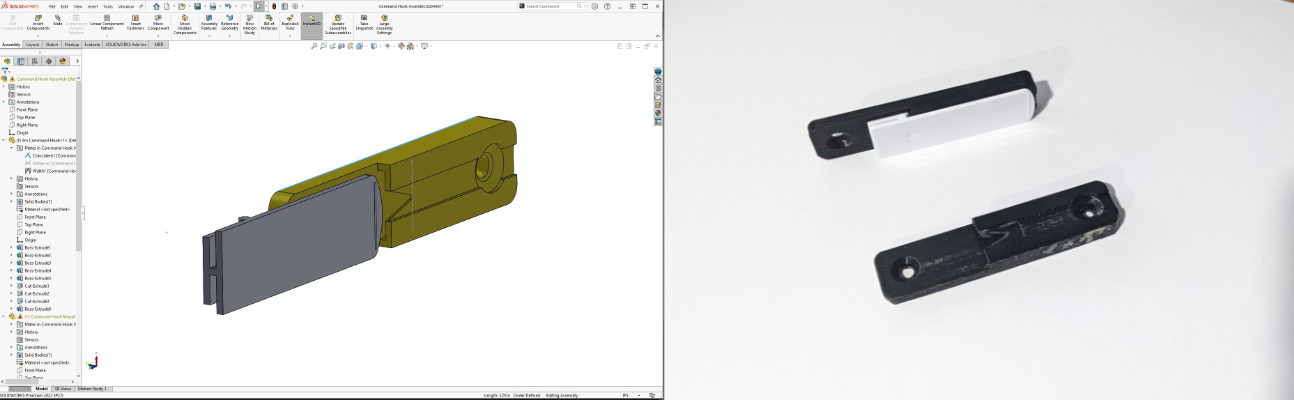

I was looking at MoCap helmets for LipSync/Facial Capture and was a little putoff by the pricing. I ordered a $20 bike helmet from Amazon...two 3/16" aluminum rod from Home Depot, amd some 3d printing. Viola! The helmet mounts were a compound curve so I used Rhino 3d Nurbs modeling to generate the models. The prints fit the surface very well. I need to elongate the rods to the rear of the head to add a counter-balance weight to improve comfort levels for long sessions.

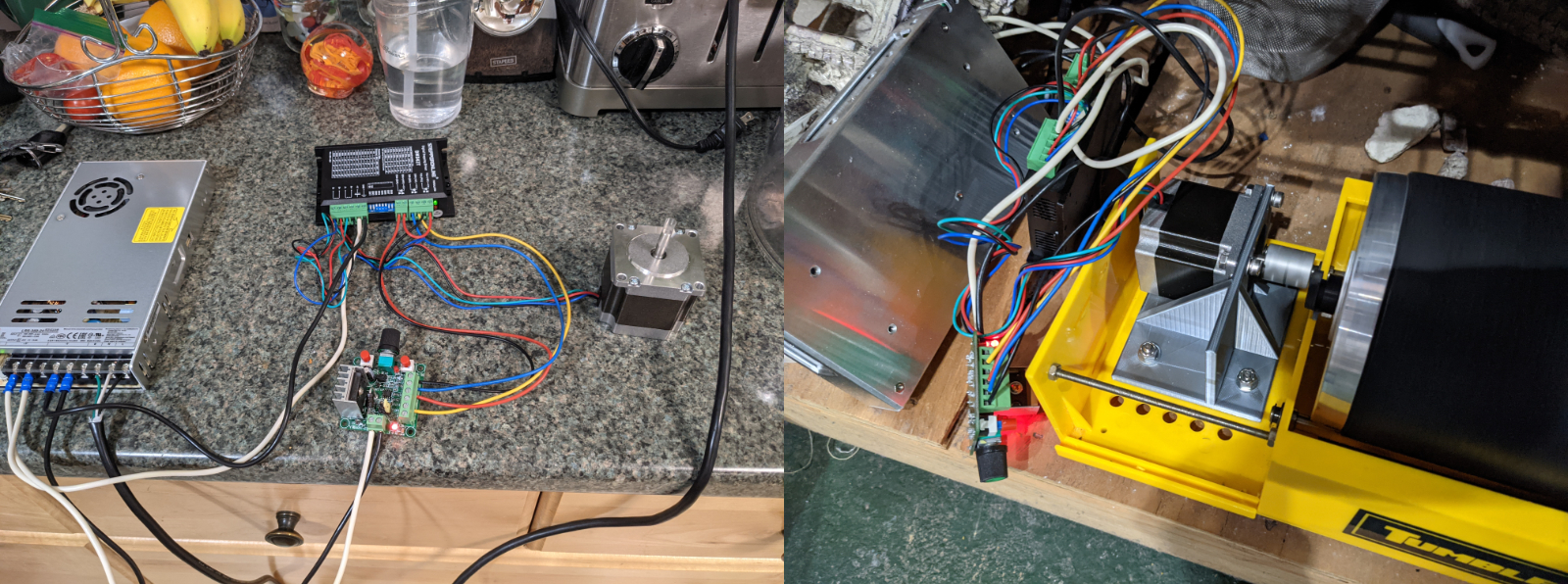

Our rock tumbler motor was on its last leg and rather than replace it with something similar I figured I'd order a stepper motor/driver/power supply and throw together something more powerful with better fine control on RPMs. Designing/printing a new motor mount was probably the easiest part of the whole process. Luckily wiring this up was just an internet search away. :)

After adding a diverter to my shower for an additional shower fixture, I realized I couldn't find a shower caddy with enough clearance to use. I drew up a multi-piece extender that would trap the shower pipe between each half. Some stainless steel screws and everything has been holding up very well.

Putting up the Christmas Tree and the stand has a captive nut that had rusted and broken off. Made a new threaded 3d printed one that worked almost good as new. Need to shift to an industrial filament that handle stresses like metal.

The camera mount for my favorite tripod broke. I bought a new tripod but it wasn't very good. I drew up a new mount for my old tripod and printed one and some spares just in case. Back to using my old favorite tripod!

Pool filter plug hand wrench broke so I re-designed it to fit on a 1/2" socket drive. Much easier to screw and unscrew the winter plug in.

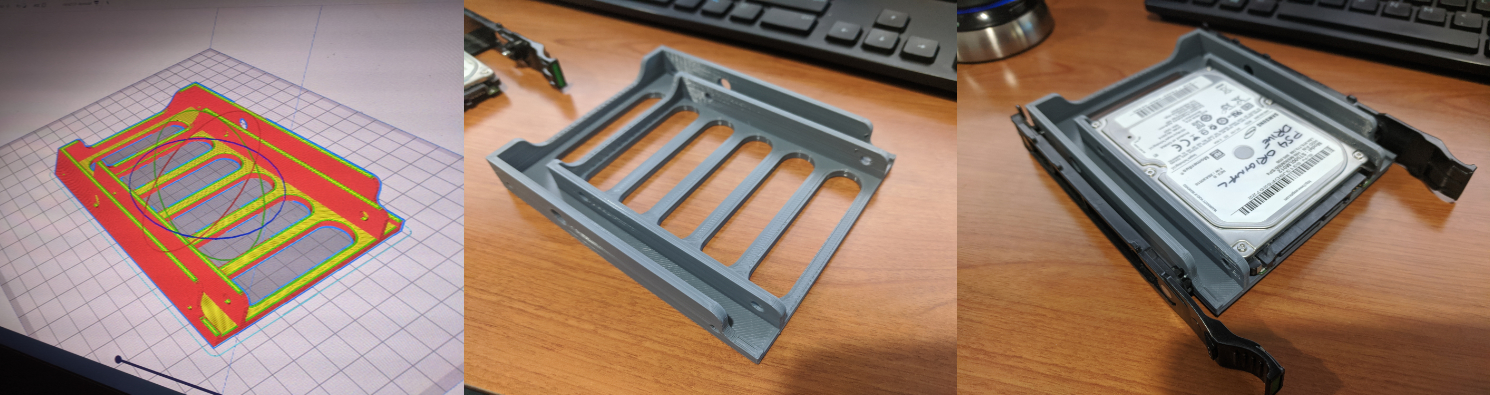

Why order a hard drive mounting adapter when you have Fusion360 and a 3d printer?

When the replacement knobs don't fit your stove...time to draw up and print some adapters so they fit nice and snug.

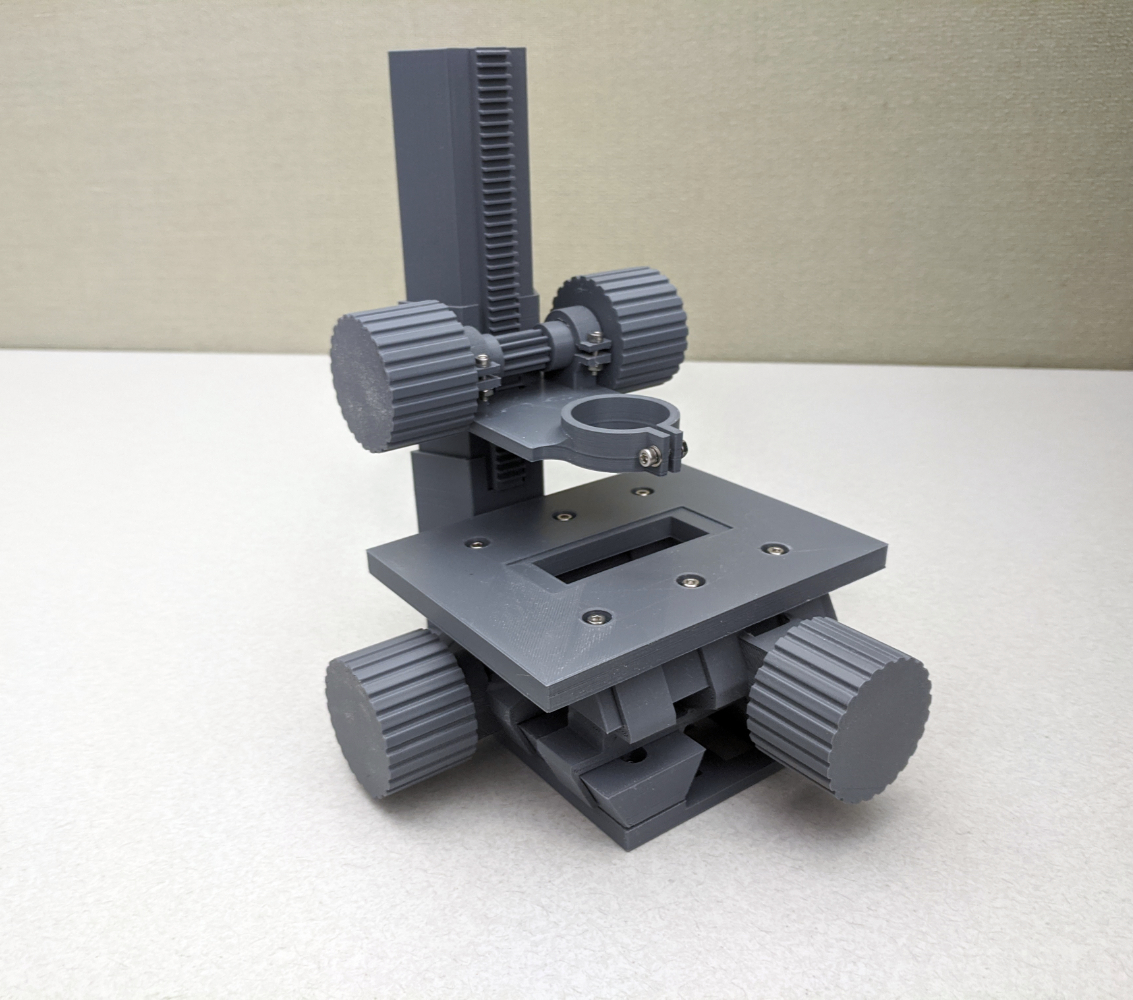

Did not design this! Downloaded from Thingiverse, designed by Ovidiu Hurducas. Definitely the most complicated piece I've printed. Rack and pinion gears worked really well.

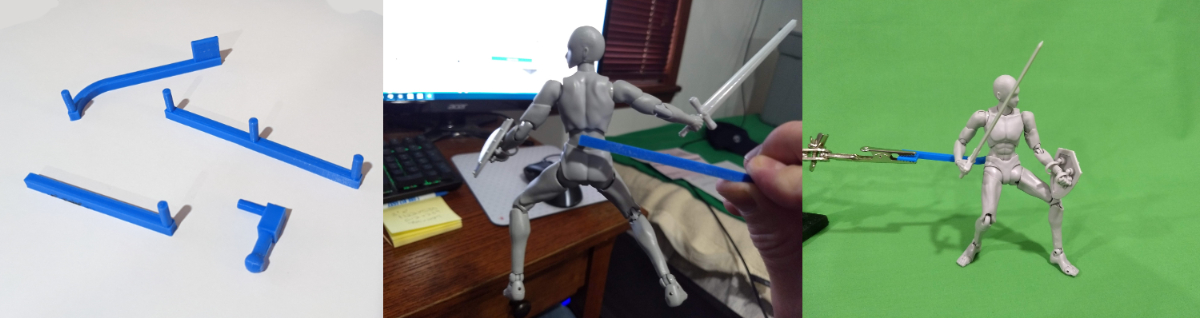

Was experimenting with a stop-motion armature and these extensions I designed/printed really helped masking off the work in After Effects.

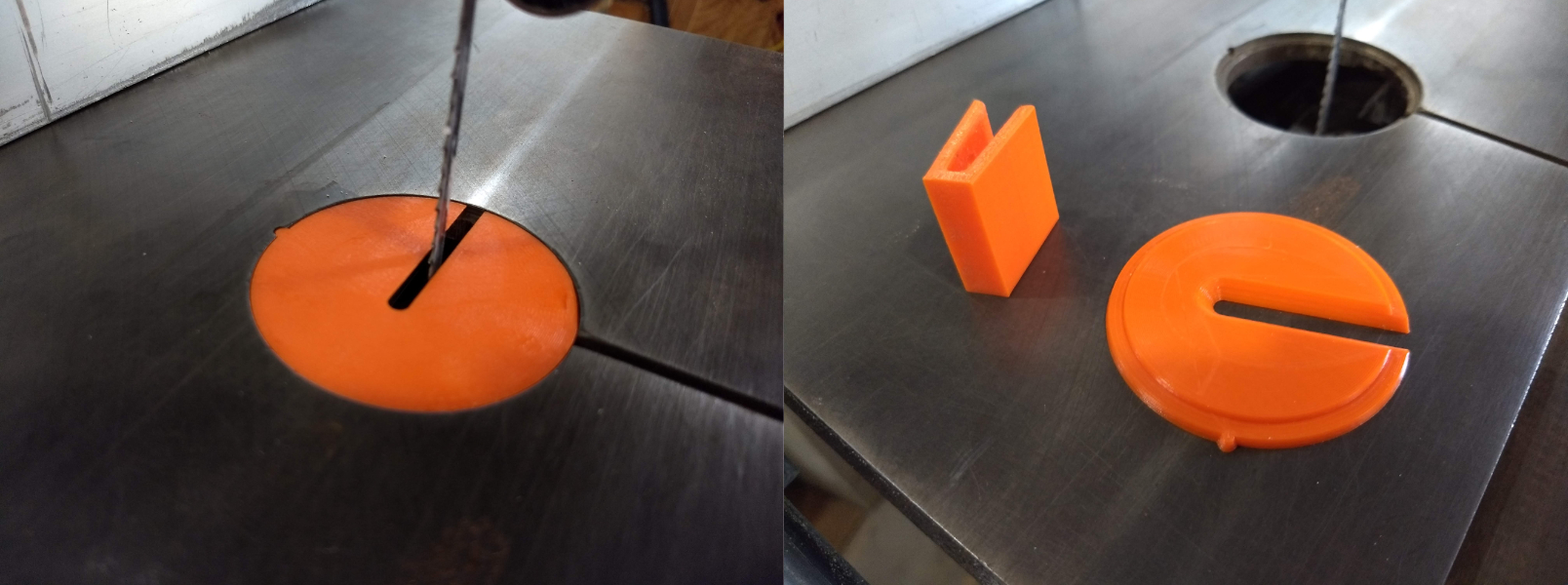

When your bandsaw blade insert is completely chewed up...draw up and print a new one.

My first 3d print off of my own 3d printer :)